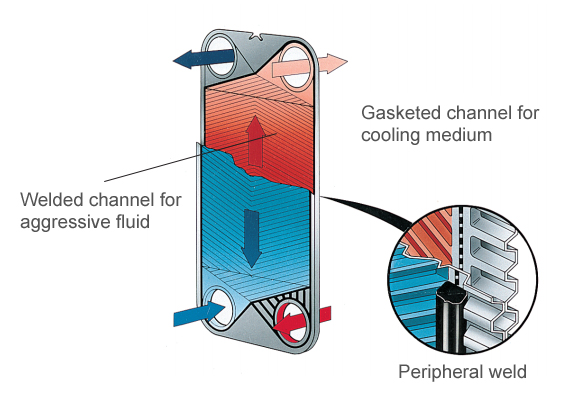

Industrial semi-welded gasketed plate heat exchangers are used when gaskets are not suitable as one of the process media. Semi-welded GPHEs can also take a higher design pressure compared to fully gasketed plate-and-frame heat exchangers.

In the Semi-welded heat exchanger the refrigerant flows in laser-welded, sealed plate channels, and in the opposite channel the liquid brine flows in gasketed channels.

Semi-welded GPHEs are used in refrigeration applications as:

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The sealing between the plates on the Industrial semi-welded line alternates between laser welds and gaskets. The laser welded channel allows use of fluids that are not compatible with normal gaskets and also allows for higher design pressure than fully gasketed plate-and-frame heat exchangers. Additionally, the Alfa Laval RefTight? sealing system guarantees equal sealing force over the entire porthole gasket.

Industrial semi-welded line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimal performance. The CurveFlow? and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

The Industrial semi-welded line can be configured in many ways. The animation shows single pass configuration of a fully gasketed plate-and-frame heat exchanger. The flow principle of a semi-welded heat exchanger is the same. The difference is that every second channel is sealed with a laser weld instead of a gasket. Multi pass with 2 or more passes on each side is also possible.

It's important to understand that all gasketed plate heat exchangers are not the same. The features highlighted below are important components to look for in a GPHE, and when combined, these features offer extensive benefits, such as reduced total cost of ownership, higher efficiency and increased staff safety.

The sealing weld is positioned separately - outside the ring gasket, which ensures equal sealing force over the entire port hole gasket, guaranteeing higher performance through the welded channel.

The sealing weld is commonly placed inside the ring gasket groove. This combined with an uneven port hole groove can lead to gasket material stress and can eventually lead to gasket failure.

One of the most important features of a plate heat exchanger, the distribution area ensures full use of the heat transfer area and minimizes fouling.

An inefficient distribution area with uneven flow causes maldistribution and fouling build up.

A glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance. Fastening to the plate is improved by having five fastening points.

Other gasket designs, such as snap-in gaskets, only have one fastening point to the plate. If this one point is lost, there is no gasket fastening function.

Model M10-BW

Model MK15-BW

Plate heat exchangers have an essential role in most applications. If they function poorly, they may lead to lower product quality, reduced safety and higher energy costs. And if they fail, they can lead to costly downtime and major losses in production. This makes it important to perform maintenance – and important to do it correctly.