Alfa Laval separators optimize tall oil production

Increased yield, higher product quality and a more sustainable process were some of the improvements Swedish pulp producer Södra Cell experienced when upgrading the tall oil plant in its Värö mill to a TOPP5000 system. The new plant was supplied by HEAD Engineering and is based on Alfa Laval high-speed separators.

DATE 2023-11-28Industry development

The declining paper market is putting pressure on pulp producers to find new sources of income. Many have developed profitable side businesses where they extract and sell by-products from the mills’ processes, for example tall oil, turpentine and lignin. These companies are making the most of their raw materials and have developed a more sustainable business.

Increasing profitability by selling tall oil

Just like many other chemical pulp mills around the world, S?dra Cell V?r? has created a new revenue stream by extracting tall oil from its chemical recovery loop. The old tall oil separation system needed replacing. When the management team decided to upgrade it they immediately understood a system based on high-speed separators would be best for capacity per installation area, product quality and yield. A decisive factor was that the new system had a much smaller footprint, which allowed S?dra Cell to expand capacity in an existing building while leaving space for future expansion.

Higher yield and product quality

The new system was installed in 2012 and it produces 5 tonnes of crude tall oil per hour. The recovery yield is more than 97%. Ove Johanzon is Senior Process Engineer at S?dra Cell. He is very satisfied with the new tall oil plant and says;

The system we invested in was the most modern on the market. It allowed us to increase capacity on the available floor space and product quality has improved. Other benefits include the low consumption of sulphuric acid and that it is a continuous, fully automatic process”.

Ove Johanzon, Senior Process Engineer at S?dra Cell, is very satisfied with the new tall oil plant.

Fast facts

The customer

S?dra Cell V?r?, Varberg, Sweden. S?dra Cell’s V?r? mill produces softwood pulp and it has been developed continuously since it was built in 1972. The mill is currently being expanded, increasing annual production from 425,000 to 700,000 tonnes.

The challenge

To increase tall oil production capacity without increasing the installation area. The solution

A TOPP5000 system with a production capacity of 5 ton tall oil/h, based on Alfa Laval separation technology.

Benefits

- More than 97% yield, significantly higher than what is achievable with conventional technology

- Less chemicals used per produced m3 tall oil

- Higher utilization of raw materials thanks to more efficient recovery of tall oil

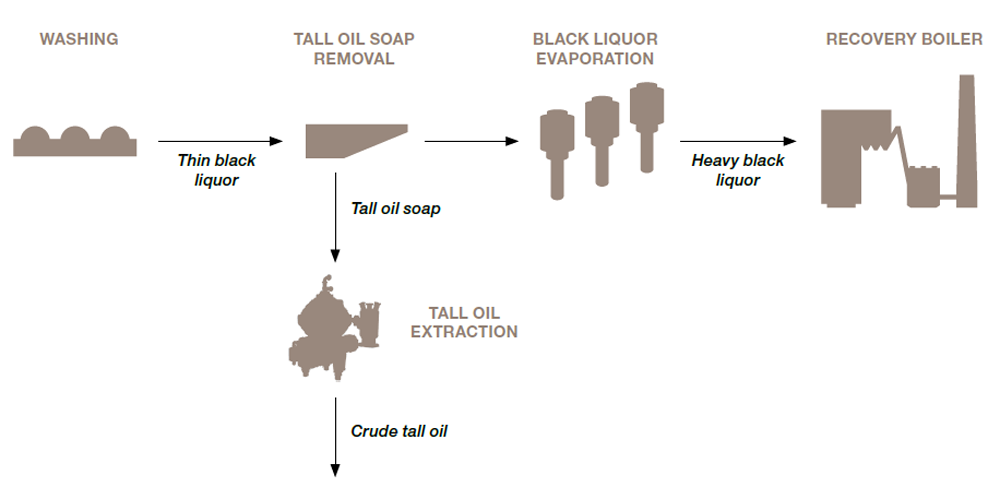

Process overview

Tall oil soap is separated from the black liquor just before the evaporation system. This is done by skimming off the soap in settling tanks. The soap is processed and acidulated in the tall oil plant where crude tall oil is extracted in an Alfa Laval high-speed separator. The separator uses centrifugal force to separate tall oil from brine and sludge. The separation process is continuous and space efficient thanks to the exceptionally high centrifugal force in the separator.

Reduced fouling and increased capacity

Removing tall oil soap from the process is important to avoid unnecessary fouling in the black liquor evaporators. Some mills burn the soap in their recovery boiler instead of extracting tall oil from it. This means the mill burns a valuable asset instead of selling it, and it places an unnecessary load on the recovery boiler, resulting in lower capacity.

In cooperation with HEAD Engineering

The tall oil production system installed at S?dra Cell V?r? is based on established separation technology from Alfa Laval Celleco, further developed by HEAD Engineering.

About TOPP5000

TOPP is short for Tall Oil Production Plant and the TOPP5000 system has the capacity to produce 5 tonnes of crude tall oil per hour. The system is part of HEAD Engineering’s PINOLA technology platform, offering process solutions for black liquor, black liquor soap and crude tall oil.