Fish oil processing

The thriving fish oil market presents a significant opportunity for fish processors. With rising prices and growing demand for premium fish oil, investments that enhance yield and quality offer excellent returns.

Alfa Laval’s processing systems are renowned for delivering exceptional yields. They enable you to produce fish oil of the highest quality with minimal FFA and moisture levels. Whether you are producing cold-extracted or hot-extracted fish oil, we have the ideal solutions for you.

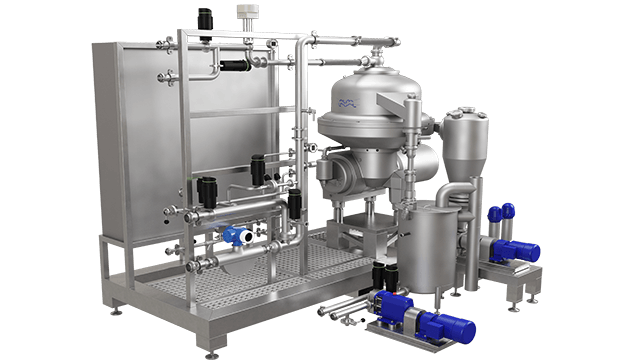

Complete systems for fish oil and extraction

Alfa Laval provides complete processing systems and individual components for the different stages of fish oil production, including krill oil extraction – all designed with a focus on cleanability, hygiene, yield, and reliability. Thanks to low-temperature processing, minimal oxidation, and exceptional water removal, Alfa Laval’s oil extraction systems consistently produce fish oil of the highest possible quality.

Process description

A typical fish oil process comprises four main stages: mincing, heating, separation, and vacuum oil drying.

1. Heating

After the initial grinding stage, the raw material is heated. This causes the proteins to coagulate, and oil is released. The design of the heating stage significantly impacts the quality of the final fish oil and the yield of the overall process. Alfa Laval heating systems are engineered for fast and precise heating, enabling cold “virgin oil” processing as well as conventional heating to 95 °C. Advantages include:

- High-quality oil with excellent organoleptic properties and low FFA levels

- Preservation of the oil’s natural colour without discolouration

- Extraction of oils with high levels of natural antioxidants and vitamins,

- Minimal release of volatile compounds, resulting in low BOD levels in the wastewater

- High yield

2. Separation

In the following process stage, the oil is separated from other components, such as protein and water. Alfa Laval systems utilize centrifugal separation in decanters and separators for this task, which offers numerous advantages over traditional fish press water processing:

- Significant increase in oil yield thanks to our unique separation equipment

- Purer oil with almost no water content

- Food-grade hygiene standards are met, enabling food-grade processes

3. Vacuum dryer

When producing high-quality oils, the final stage involves an oil vacuum dryer. In this module, moisture levels are reduced to as low as 0.05%, and absorbed air is removed. This enhances product quality, ensures oil clarity is maintained over time, and prolongs the oil’s shelf life.

Raw materials

- Whole fish

- By-products from filleting operations

- Shrimp

- Krill

Upgrade your process to boost yield and product value

By upgrading your existing fish oil production lines to Alfa Laval technology, you can improve both yield and product quality. Our oil extraction systems enable you to increase process yield and meet the highest standards for food-grade production.

The Alfa Laval Centriflow process has minimal retention time and operates at low temperatures to ensure outstanding product quality. The result is oil with minimal oxidation, moisture and FFA content, and high levels of valuable Omega 3 fatty acids.

Contact our application and equipment experts to discuss how we can assist you in upgrading your existing equipment and processing line.

Refining systems

Apart from equipment and systems for fish oil extraction, Alfa Laval also offers reliable and easy-to-operate components and systems for edible oil refining. Our refining solutions are perfect for treating oil intended for pet food, aquaculture feed, and dietary supplements. They can remove persistent organic chemicals, such as traces of PCB or DDT, and perform deodorization at low temperatures to preserve heat sensitive fatty acids in their natural, bioactive form.

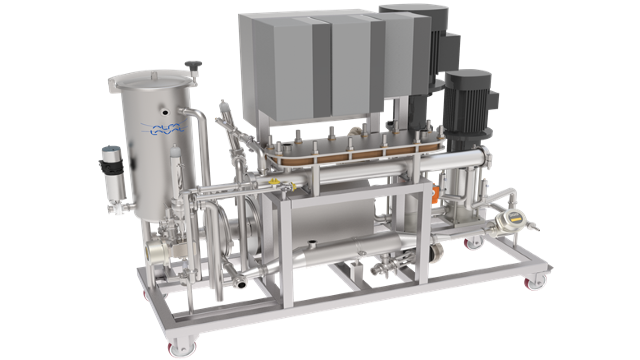

Alfa Laval Foodec Oil Plus – setting a new standard

The new Alfa Laval Foodec Oil Plus is revolutionizing fish oil production. Thanks to its innovative design, Foodec Oil Plus extracts more oil than other solutions, ensuring maximal utilization of the raw material.

- Maximal oil yield due to special new decanter design

- Very pure oil, requiring minimal further processing

- Easy operation and maintenance

- Low total cost of ownership and short pay-back time – often less than 1 year

- Available as a plug-and-play skid

- Minimal change in your existing process, only one new component

快速、優(yōu)質(zhì)的服務(wù)

阿法拉伐是您值得信賴的服務(wù)合作伙伴,無論何時(shí)何地,即使在最偏遠(yuǎn)的地方,您都可以信賴阿法拉伐為您提供的及時(shí)、優(yōu)質(zhì)的服務(wù)。我們的全球服務(wù)辦事處網(wǎng)絡(luò)可在您運(yùn)營(yíng)的各個(gè)階段提供專業(yè)支持,包括故障排除、定期維護(hù)、高級(jí)性能審核和預(yù)測(cè)性維護(hù)。

利用我們的遠(yuǎn)程服務(wù),我們可以通過數(shù)字渠道提供即時(shí)協(xié)助。如果您需要現(xiàn)場(chǎng)支持,我們可以迅速派遣現(xiàn)場(chǎng)技術(shù)人員前往全球任何地點(diǎn)或港口。

我們強(qiáng)大的本地網(wǎng)絡(luò)使我們成為全球運(yùn)營(yíng)公司的理想服務(wù)供應(yīng)商,促進(jìn)更緊密的合作并減輕行政負(fù)擔(dān)。阿法拉伐為您提供全面的服務(wù)解決方案,無論您身處何地,我們都能確保您的業(yè)務(wù)不間斷,值得您信賴。